Strategic OEM Partnerships

January has come and gone, and what a busy month it has been for Jenks & Cattell Engineering! We’ve started the year strong, securing £2.6m turnover sales from 3 OEMs in the off-highway ad truck industry.

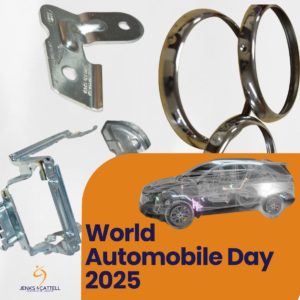

Notably, two of these OEMs have been our loyal and strategic partners for over two decades, sourcing laser-cut fabrications, welded assemblies, and metal pressings from our Wolverhampton plant.

Metal Press Tool Resource Projects

Our resource projects were executed with remarkable speed, thanks to our dedicated NPI (new product introduction) team, ensuring supply chain continuity. For our new truck OEM partner, we managed to dispatch metal parts just two weeks after receiving the initial resource tools; working through Christmas to achieve this feat. This project involved resourcing approximately 50 tools, a significant undertaking compared to our previous record of 290 press tools.

Our 250t, 400t, and 750t progression presses, along with a mix of laser fabrication, welded assembly, and form tools will be utilised with new business. Our team supported the development process and met our partners’ tight schedule demands, delivering products complete with ISIRs to the required quality standards. All our quality procedures adhered to IATF standards.

In 2025, our NPI team has already introduced around 30 metal assemblies to our manufacturing plant. We are currently conducting VAVE (Value Analysis/Value Engineering) exercises, as many parts have been identified as over-engineered. The Jenks & Cattell Engineering NPI team excels in pinpointing the most efficient production routes, which not only speeds up the process but also reduces costs.

If you would like more information on completing a resource, you may find the below articles useful:

Alternatively please contact our sales team at sales@jcel.co.uk

Useful Information:

Grow as We Grow: Growth and Innovation in Sheet Metal Engineering

Important Factors in Choosing a New Metal Fabrication Partner