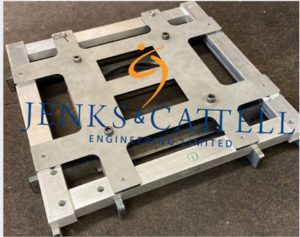

Jenks & Cattell Engineering have been working alongside a new customer since the end of 2019 to develop a prototype into a production volume part.

Throughout the prototype process, we have supported our customer’ design changes to create a cost-effective manufacturing processes to meet crash tests and satisfy design requirements.

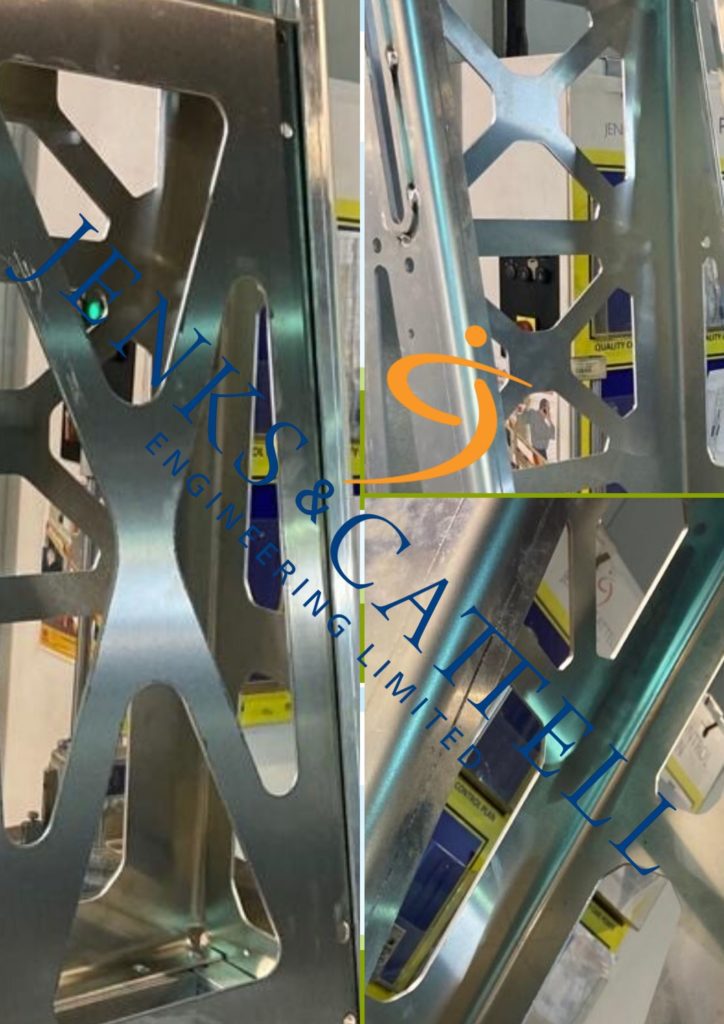

The product is for a sliding seating system within a military vehicle, where the Jenks & Cattell Engineering team are working with two specifications of aluminium including 6082 T6 hardened, which is known for its strength and corrosion resistance.

The laser fabrication assembly is mig welded with rivet nuts inserted; with an expected turnover of over £150k.