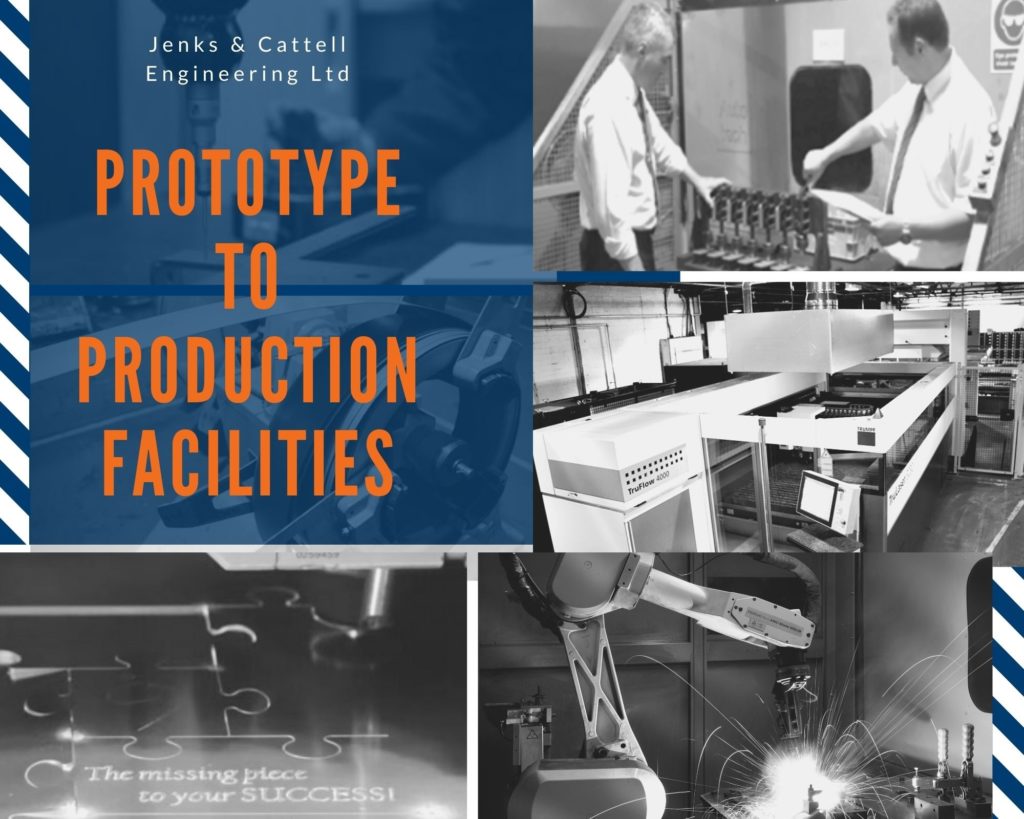

Supporting Prototypes to Production Volumes

Jenks & Cattell Engineering take pride in offering a complete engineering service to support the lifetime of projects and aim to reduce issues prior to production.

With the vast amount of equipment and personnel, prototype development and volumes are supported prior to production volume manufacturing expertise.

Prototypes can be manufactured by Jenks & Cattell Engineering, with the review of tolerances to ensure the component is feasible, components can be checked to CAD drawings on our CMM, and we can continue to manufacture components either on the laser machine without tooling, or with prototype press tools until we have a ‘fit-for-function’ component for production purpose.

Our engineering team work closely with customers to reduce costs, and metal components are designed to be manufactured with a focus on material optimisation. Components will be reviewed, and the most cost-effective manufacturing routes will be specified to budget and longevity.

Our metal fabrication expertise and capacity to manufacture prototypes prior to production volumes to ensure parts are:

- Fit to Function

- Feasible

- Correct Tolerances

- Not “Over-Engineered”

- Correct Strength and Usage of Material

- Time and Costs Suit Customer Specifications

- Review If Any Further Changes Required

Jenks & Cattell Engineering have two laser cutting machines in-house which can produce low volume prototypes and is complimented by our press brake and welding for a complete fabrications and assemblies.

In addition to this, for more complex metal stamping’ we can provide soft stamping tools and/or plastic 3D printed components to review for feasibility purposes.

For more information on the support of your projects life cycle, please contact our team: sales@jcel.co.uk or 01902 305530