Jenks & Cattell Engineering is renowned for offering a range of comprehensive services under one roof. From laser cutting low volumes and prototypes to metal pressing high-volume complex parts and manufacturing metal assemblies with our CNC machining and welding capabilities.

We are excited to announce our latest investment in machinery to enhance our engineering solutions and provide innovative support for our customers’ prototype ideas before mainstream metal production.

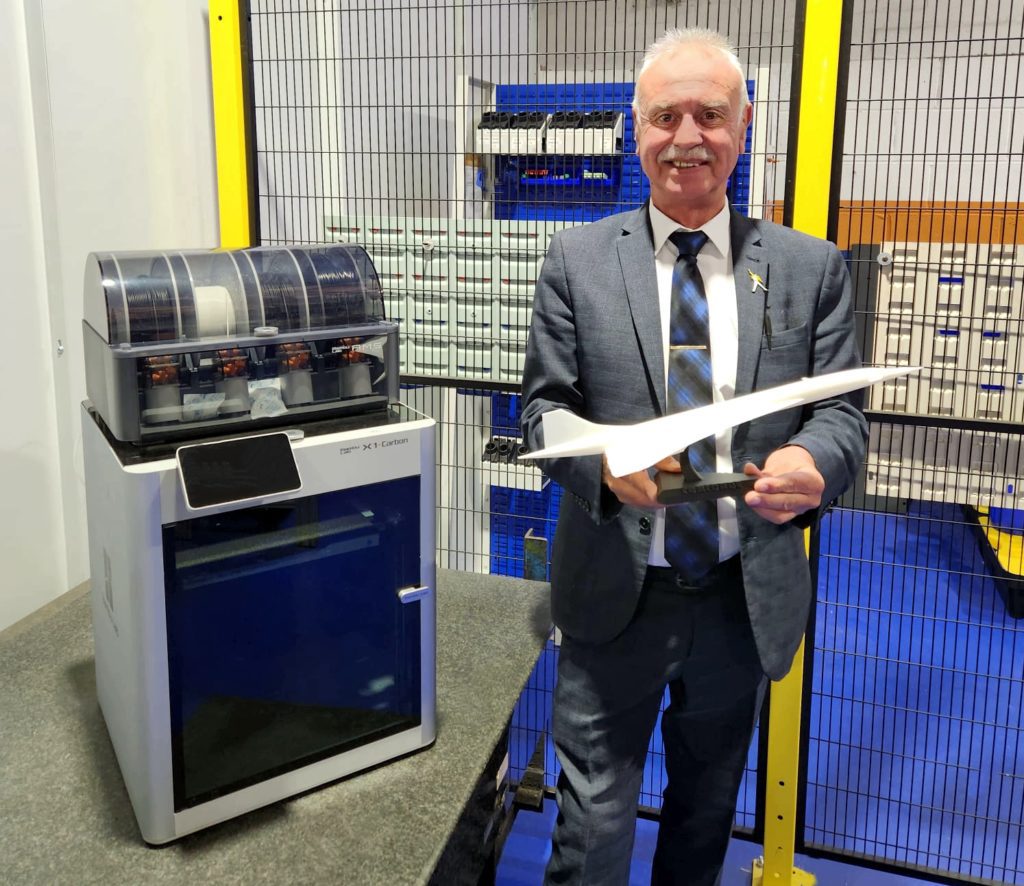

Our first 3D printer is the Bambu Lab X1, featuring a build volume of 256 x 256 x 256 mm. Its auto bed levelling with force sensors and micro lidar precision ensures we produce parts with the required quality and accuracy. It will also give us extra options and capabilities when manufacturing jigs and fixtures in-house, and at a faster pace.

How can our partners benefit from our 3D printer?

- Create prototypes with minimal investment

- Test simplified engineering solutions to achieve cost savings or improve design functionality

- Assess manufacturing feasibility and functionality before production

- Enjoy shorter lead times as we produce jigs and fixtures in-house

For those familiar with our Technical Director, Craig Jeavons, you know his passion extends beyond sheet metal manufacturing to all things Concorde. To celebrate our new machine, we presented Craig with his very first 3D-printed Concorde to add to his collection.